![]()

![]()

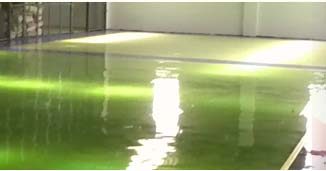

Epoxy floor paint or epoxy paints or floor coatings is basically a thermo setting resin used chiefly in strong adhesives and coatings and laminates. Epoxy flooring are often used on floors because of their reputation for toughness and durability from wear and chemicals. Epoxy flooring or Epoxy Floor Paint have excellent outstanding chemical resistance, durability, low porosity & strong bond strength. Hence it is applied on floors to save it from wear and chemicals. Epoxy is a thermo setting resin, which is used in adhesives, coatings and as a finish cover over repaired or patched concrete to provide an attractive texture and uniform finish. Industrial Epoxy Flooring, monolithic epoxy flooring is available in choice of colors.

Epoxy floor paint or epoxy paints or floor coatings is basically a thermo setting resin used chiefly in strong adhesives and coatings and laminates. Epoxy flooring are often used on floors because of their reputation for toughness and durability from wear and chemicals. Epoxy flooring or Epoxy Floor Paint have excellent outstanding chemical resistance, durability, low porosity & strong bond strength. Hence it is applied on floors to save it from wear and chemicals. Epoxy is a thermo setting resin, which is used in adhesives, coatings and as a finish cover over repaired or patched concrete to provide an attractive texture and uniform finish. Industrial Epoxy Flooring, monolithic epoxy flooring is available in choice of colors. |

|

|

|

|

|

|

Our Video

Merits of Epoxy Flooring :

|

|

![]() Download

- Process Chart Epoxy Flooring

Download

- Process Chart Epoxy Flooring

|

|

|

![]() Our

Supply Network - Spread Over PAN India

Our

Supply Network - Spread Over PAN India

|

Gurgaon Gwalior Rohtak Badli Rewari Ghaziabad Roorkee Bhubaneswar Raipur Assam Thiruvananthapuram Agartala Puducherry Karnataka Silvassa Nagpur Guwahati Tripura Kohima Kala Amb Noida Bawal Vijaywada Datia |

Faridabad Mathura Bhiwadi Uttranchal Kundli Amritsar Andhra Pradesh Ranchi Pondicherry Chandigarh Bihar Pune Lucknow Punjab Kerala Daman Sri Ganganagar Patna Uttar Pradesh Kashipur Agra Batala Coimbatore Hapur |

Meerut Agra Rudrapur Greater Noida Sonipat Ballabhgarh Karnataka Gandhinagar Kanpur Varanasi Jammu & Kashmir Hyderabad Bhopal Dehradun Rajasthan Madhya Pradesh Delhi Ludhiana Jaipur Pant Nagar Chennai Cochin Basavanpura Loni |

Haridwar Rampur Parwani Manesar Panipat Bahadurgarh Gujarat Arunachal Pradesh Bengaluru Chennai Orissa Srinagar Chhattisgarh Mumbai Kolkata Tamil Nadu Maharashtra Goa Dibrugarh Haridwar Mumbai kochi Panaji Avadi |

|||